Whenever we go to the organic store to buy something like bread, Beth always ends up getting five other things and spending three times as much! And the same happens with me when we go to the hardware store – this week we went to buy some nails and came back with this awesome drill press on special for only R$276!

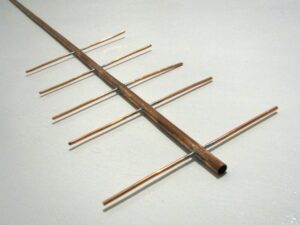

The first thing I did with the new drill press was to make a start on the net antenna by drilling the holes for the wave-guides and soldering in the first one. It’s quite difficult to solder such large areas of metal because it acts as a heat sink, so I first tinned the areas (added solder and filed flat again) to be soldered and then redrilled them before soldering each wave-guide into place.

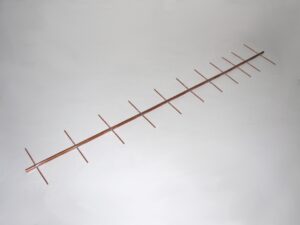

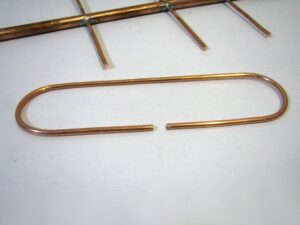

The position and lengths of the wave-guides looks kind of haphazard and random, but actually they’re very precise to within a fraction of a millimetre so that the antenna is perfectly tuned to 850MHz to match the 2G signal coming from our local tower. I used John Drew’s Yagi Calculator which allows you to calculate the exact positions and lengths of your elements by entering the details of the materials you’re using and the desired frequency and gain of the final unit. The folded dipole (last picture above) was the most difficult bit to get right, the inner radius of the curves needed to be 35mm and the total width 173mm with the small gap in the exact centre. I got it pretty close to sub-mm accuracy.

We’ve been wondering what to do about washing at the land using very little or no power but more effective than hand washing. Then today (Sunday) Beth came up with an ingenious idea, she drilled some big holes in a toilet plunger turning it into an excellent manual clothes washer!